Glass Coated Steel: NOT STICK BUT FUSED

The company has experience in manufacturing glass coated steel components for the most various applications, since 1838. The tanks are made of screwed glass fused steel plates and galvanized ring stiffener fixed and sealed on a concrete slab. The storage capacities range from 8m3 to over 30,000m3 per tank. All components are produced based on your requirements.

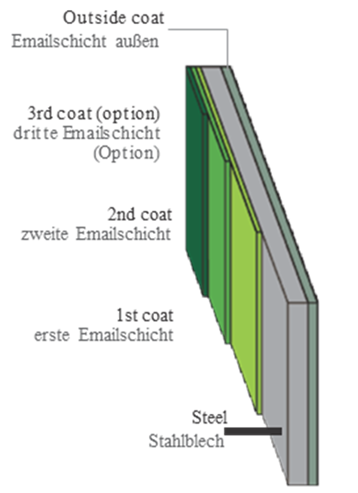

Vitreous enamel (glass) coating is the perfect system to combine the benefits of steel (highest loadbearing capacity, resilience) and glass (highest chemical resistance) in one single material. The liquid enamel fuses during one or two (depending on the required surface properties) fire processes at 850 °C to become a new material: Enameled glass coated steel.

Why Glass Coated Steel?

• High resistance to atmospheric corrosion.

• UV light resistant

• High durability

• Easy cleaning.

• NO maintenance required.

• Short manufacturing times

• Short installation times.

• Can be expandable

• Can be movable

• High efficiency and equivalent value

• Valuable over decades due to the base material for the greatest cost saving.

• Excellent life cycle balance.

• Applying for most of applications possible.

Applications

The glass coated steel plates are manufactured in different qualities depending on the particular customized application. Please find several examples of the different standards.